Location(1)Ulti(19)FANUC(10)Your(257)Stock(13053)

In the ever-evolving world of robotics and automation, finding the right stock location for your Fanuc robotic systems is crucial for optimal performance and efficiency. This guide will delve into the importance of selecting the perfect stock location for your Fanuc US systems, provide insights into the available options, and showcase real-world examples of successful implementations.

Understanding the Importance of Stock Location

The stock location plays a pivotal role in the overall efficiency of a robotic system. It determines how quickly and effectively the robot can access parts, reducing cycle times and improving productivity. A well-planned stock location ensures that the robot can move seamlessly between tasks, minimizing downtime and maximizing throughput.

Fanuc US Stock Location Options

Fanuc offers a variety of stock location options to suit different application needs. These include:

- Linear Rail Systems: Ideal for high-speed pick-and-place operations, linear rail systems provide a straight path for the robot to travel, reducing travel time and increasing accuracy.

- Rotary Tables: Perfect for applications that require multiple parts to be presented to the robot simultaneously, rotary tables offer a compact and efficient solution.

- Stacker Systems: Stacker systems are designed to store parts vertically, maximizing space and allowing for quick retrieval. They are particularly useful for applications with limited floor space.

- Bin Picking Systems: Bin picking systems enable robots to pick parts from bins or trays, eliminating the need for manual sorting and reducing labor costs.

Real-World Examples

One example of a successful implementation of a Fanuc US stock location is a manufacturing company that produces electronic components. By utilizing a linear rail system, the company was able to reduce cycle times by 30% and improve overall efficiency. The linear rail system allowed the robot to quickly move between workstations, minimizing downtime and increasing throughput.

Another example is a food processing facility that implemented a stacker system to store raw materials. The stacker system not only maximized space but also ensured that the robot could easily access the materials, reducing cycle times and improving overall productivity.

Factors to Consider When Choosing a Stock Location

When selecting a stock location for your Fanuc US system, it's important to consider the following factors:

- Application Requirements: Assess the specific needs of your application, including the types of parts, the number of parts, and the required cycle times.

- Space Constraints: Evaluate the available space in your facility to determine the best stock location option.

- Budget: Consider the cost of the stock location system, including installation and maintenance, to ensure it fits within your budget.

Conclusion

Choosing the right stock location for your Fanuc US robotic system is essential for maximizing efficiency and productivity. By understanding the available options, considering your application requirements, and evaluating your facility's constraints, you can select the perfect stock location for your needs. With the right stock location, your Fanuc robotic system will operate at peak performance, driving your business forward.

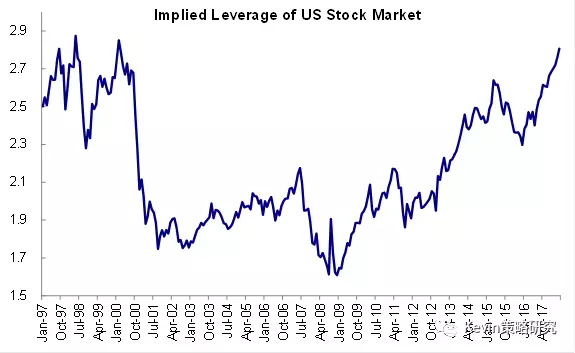

NYSE Composite